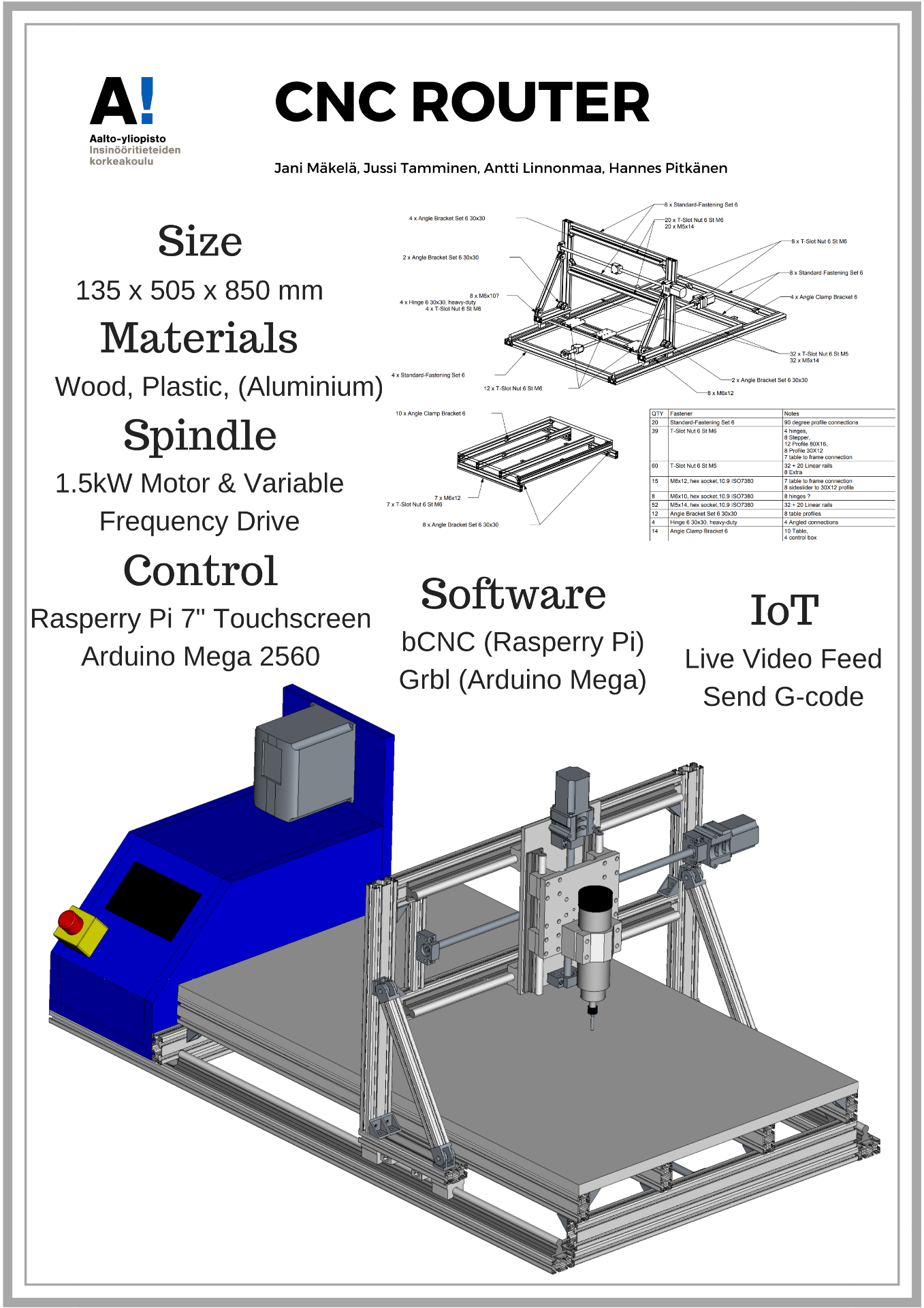

CNC Router

The CNC Router was designed and build as a part of Mechatronic Exercises course on spring 2018. Later on that spring and summer it was further assembled and implemented on two Advanced Project on Mechatronics courses. This was my first larger scale project during the bachelor's degree at Aalto and it gave me an excellent experience on how to do a mechatronic design project.

Project brief

This project was started on January 2018. Our task was do design and build a mechatronic device, but otherwise the topic was free. We wanted to make something that could actually be useful and it should be properly made. Our first idea was to make a laser cutting machine, but we figured out that we could encounter some problems when ordering the laser tube. The second idea was this CNC router which we then selected.

Design phase

During the spring 2018, we spend a lot of time in the design phase to make sure that our design will be functioning. The CAD modeling was made using Creo Parametric 3.0, which gave us good experience in modeling with this software. We also had to take care of the manufacturability since we had to be able to make the parts and then assemble them. I was participating remarkably in the mechanical design and modeling, so this provided me a good experience in that. I also did learned how to make kinematic joints with Creo for studying the motion of the machine.

Assembly

After the design phase we started to assemble the machine. The frame was made of aluminum profiles and they were ordered according to the drawings and the pieces were ready cut and machined. This is where careful design paid off because the frame assembly didn't take much time. The blue control box was build of 24 mm thick birch plywood and we made that by ourselves. The next thing we did was the machining of the aluminum plates that hold the spindle. We did the machining ourselves as well. After all, there was a lot of manufacturing to do by ourselves and I think it was a good experience for me. It improved my design skills on behalf of manufacturability and also practical skills in assembly and manufacturing process.

Then, during the summer we assembled and tested the CNC router. It's now located in mechanical engineering laboratory K3 basement where it can be used as well.